THE PROCESS

Gas welding operates by delivering a mixture of oxygen and fuel gas through a torch, generating an intense flame capable of melting metal. This process involves melting the material at the junction of two components, resulting in what is referred to as a weld pool. As the weld pool cools, it solidifies and fuses the pieces, creating a robust joint. To ensure a strong connection, the welder must carefully maneuver the flame at a slow pace, allowing the joint to cool without exposure to oxidation, which can lead to weak, brittle bonds.

TYPES OF GAS WELDING

While electrical welding methods have surpassed gas welding in numerous applications, the portability, efficiency, and ease of use of gas welding ensure that it remains a popular choice across various manufacturing sectors. Gas welding encompasses several primary types that utilize various gases, including acetylene, gasoline, MAPP (methylacetylene-propadiene propane), butane, propane, and hydrogen.

APPLICATIONS

Gas welding services are predominantly utiliSed for repair tasks. This method excels at closing gaps between components more effectively than many alternatives. Additionally, gas welding finds use in various other applications, including:

- Fabrication

- Automotive

- Construction

- Manufacturing

- Maintenance

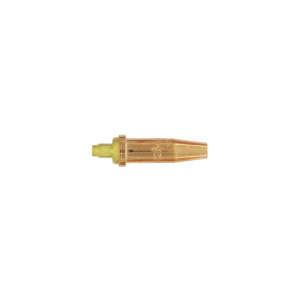

PRODUCT RANGE

Explore Our Extensive Product Range & Equipment